| Modelo | Máquina de grabado láser FLYTOO 9060 B |

| Tipo del laser | 10.6um, sellado co2 del laser de cristal |

| Energía del laser | 100W |

| Área de trabajo | 900*600mm |

| Configuración opcional | Levante la tabla, tabla del panal, |

| Modo de enfriamiento | Refrigeración por agua |

| Velocidad de exploración del grabado | 0-1000mm/S |

| Velocidad de corte | 0-600mm/S |

| Análisis de máxima precisión | 2500DPI |

| Mini-formar carácter | Character2.0 chino * 2.0m m, English1.0 * 1,0 mm |

| Precisión de colocación | ≦ + 0.01 m m |

| Láser de control de energía | configuración de software 1-100% |

| Formato gráfico apoyado | DSP PLT BMP DXF AI |

| Software soportado | bordado Tiandao, photoshop, coreldraw, autoCAD |

| Puerto de Comunicacion | USB |

| Sistema Operativo | WINDOWS /WIN10 |

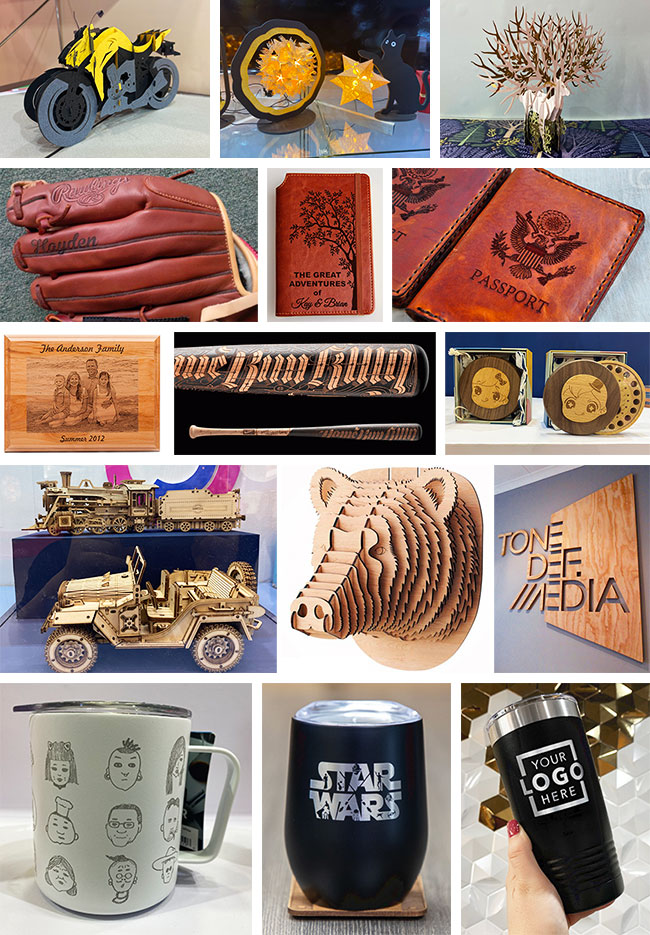

| Materiales | OLED,Acrilico, Madera, Piel Sintetica, Textil, Hule, Marmol, Ceramica |

| Energía | AC110V-220V + 10%, 50-60 HZ |

| Ambiente de Operación | Temperatura:5 C - 40 C, Humedad: 10% - 90% |

| Dimension de la Maquina | 1440*1050*1150 /90kg |

| Dimensiones de embalaje | 1490*1150*1230mm /360kg |

| Ambiente de Operación | Temperatura:20 C - 28 C, Humedad: 40% - 60% |

CO2 Laser Tube

We have catalyst plating in the inner wall of the laser tube. working life is up to 10000 hours. When compare to the same length tube, RECI W2 co2 laser tube is New firing technology is used to join metal parts and glass parts together directly. This new technology makes the high stability in W series laser tubes.

Well-Designed Details

With high precision stepping motor and high-quality reflector for strong performance. Switches and emergency button for better control. The built-in cooling fan reduces temperature of all components. With 4 casters, easy to move.

If your door is not large enough, the machine bracket can be removed to allow you to move the machine.

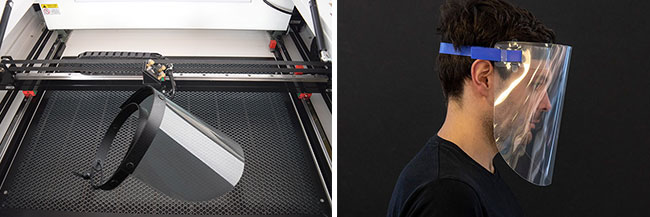

Multiple Laser Cutting/Engraving Heads

The X-1309 can be equipped with single or dual laser cutting/engraving heads. Dual heads allow two copies of the same pattern to be cut simultaneously on a single sheet of material. The spacing between the heads can be adjusted at any time (based on the repeat width of the pattern) using just a screwdriver.

Choice of Focusing Lens

We offer two focal lengths of lens for use in our standard laser heads. The 2.5” (60mm) lens is ideal for general purpose cutting and engraving, while the 4” (100mm) lens is best for cutting material over 20mm thick. The standard laser head has two lens mounting positions, so the spacing from the bottom of the nozzle to the material is the same with both lenses.

Air Assist Mechanism

The laser head includes an adjustable air assist assembly. A constant stream of compressed air protects the lens from dust or cutting vapor, and sweeps the cutting surface, reducing the possibility of flaming, scorching, or charring when cutting materials such as acrylic or wood.

Rotary Unit

Thanks to its height adjustable working table, the X-1309 can be equipped with an optional rotary unit for cutting and engraving pipe or rod around its circumference. If you need this device, please contact customer service to buy it.

Front Panel Display and Controls

The X-1309 is equipped with a high performance control system with a user-friendly interactive panel.

The high-resolution, true color TFT LCD panel lets you preview machine status and job details before processing. You can adjust parameters for different materials, or even run a processing simulation on the panel.

While processing, you will see real-time status information on the panel, and you can adjust parameters on the fly according to the results you are seeing.

Reliable Off-line Operation and Hot Restart

If there is a power failure or the emergency stop is hit, all configuration and job status information is automatically saved. After the problem is cleared, cutting or engraving can resume exactly where it left off, preventing material wastage.

Embedded flash storage in the controller lets you transfer jobs to the machine by USB, Ethernet or flash drive and finish processing offline without relying on a connection to your PC.

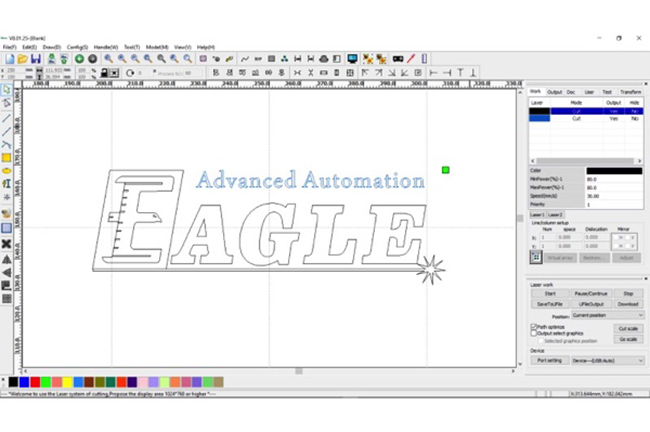

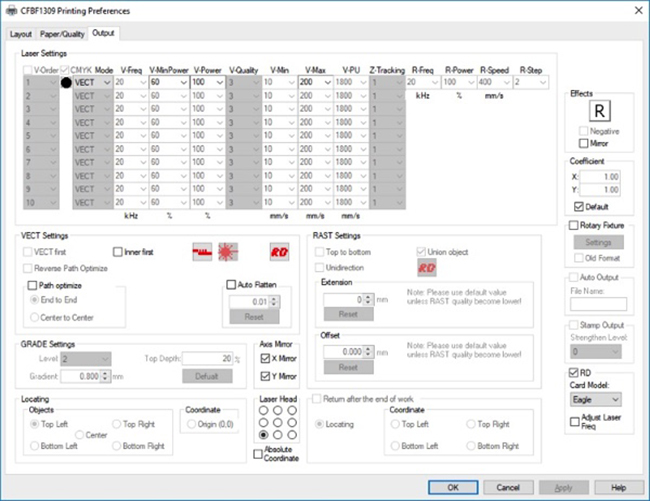

Design and Machine Control Software

We supply your machine with Eagle Works, a complete software solution for creating, editing, optimizing, and processing patterns for cutting and engraving. You can import a design from your favorite CAD or illustration program, or create an original design with the Eagle Works software. Then you can adjust the cutting/engraving order, specify the layout within the processing area of the machine, run a processing simulation, and finally control the machine directly from inside the software running on your PC.

Print Driver

As an alternative to using the Eagle Works software, you can run the machine directly from within your favorite CAD or illustration program using our print driver. This software makes the laser machine look to your computer as if it were just another printer, to which you can “print” from any application, including AutoCAD, Adobe Illustrator, Photoshop, CorelDraw, etc.

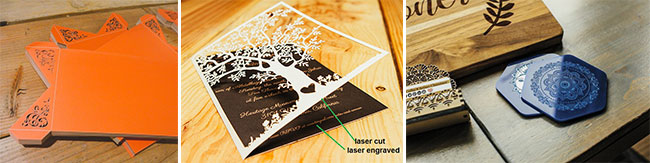

When controlling the machine through the print driver, you use color and line thickness settings in the drawing to control the laser power (cutting vs. engraving) and the order of cutting. This allows you to easily combine cutting and engraving in a single job, for faster processing and more precise control of the laser.

Half-toned photographs and other images can be laser-engraved by “printing” directly from inside your favorite image editing software. When using software that supports both raster images and vector drawing (e.g. Adobe Illustrator, CorelDraw, etc.) a simple one-step Print command can do both cutting and engraving simultaneously.

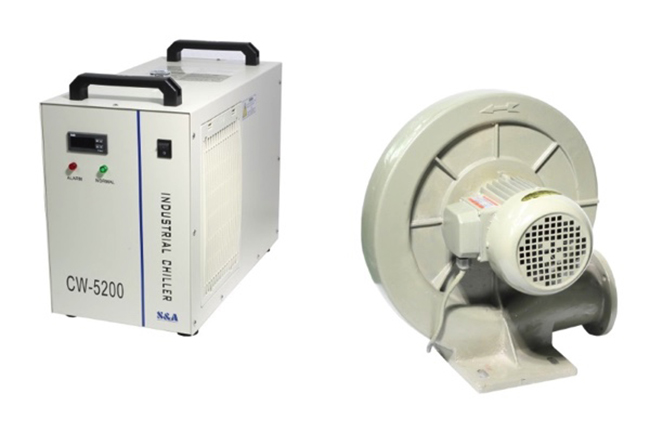

A Complete Set of Accessories

We provide a complete, ready-to-use package with all the necessary parts to get your machine up and running.

A high quality industrial water chiller circulates cooling water through the laser tube, ensuring continuous and stable laser output power.

A powerful exhaust blower maintains negative pressure within the entire machine enclosure, ensuring efficient extraction of dust and fumes from both above and below the work piece.

We supply all the ductwork needed to vent the machine to the outside.

Just connect it all together and you are ready to run your first job!

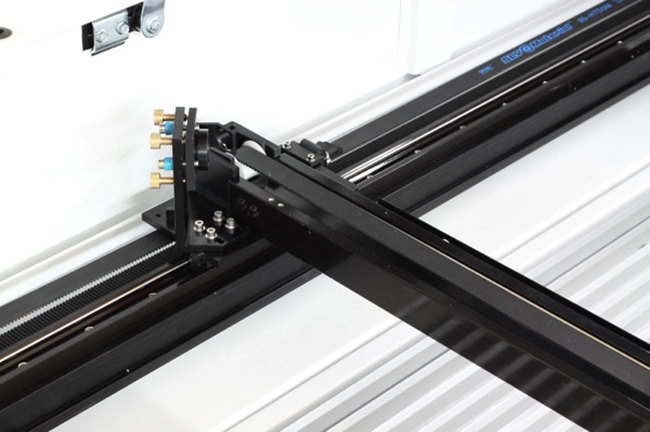

The X-1309 includes many high-end design elements that give our machines superior speed, accuracy, reliability and service life.

High Performance Motors

With Stepper motors from leading supplier, the laser head of the X-1309 can move very fast at extremely high resolution.

Robust, High-precision Slides

The linear bearings and slide rails used in the X-1309 are thicker and stronger than in competitive models, ensuring long-term stability of the laser path. That means less downtime, more productivity, and more profit.

Superior Laser Sources

The X-1309 can be equipped with single or dual 100W, 130W, or 150W glass CO2 laser tubes, all with great cost performance ratios. (Dual laser systems include two cutting heads, allowing you to cut or engrave twice as much material in the same amount of time.)

If engraving is a large part of your workload, you can increase productivity and engraving consistency with our 50W or 100W RF metal tube laser. It will allow you to get more done in less time with unmatched engraving quality.

High Quality Optics

The X-1309 is equipped with top-quality, American-made optics, to provide a consistent laser beam across the entire working area. This allows the X-1309 to achieve industry-leading cutting and engraving quality.

Superior Mirrors and Mirror Mounts

The laser beam is carried from the laser tube to the laser head by a series of mirrors, whose alignment is crucial for good performance. Our mirror mounting and adjusting system is the best in the world, designed for stability and ease of use. In most cases the machine will not require any alignment after installation, but if it goes out of calibration for any reason, three adjustment screws per mirror allow you to achieve perfect alignment with minimal frustration.

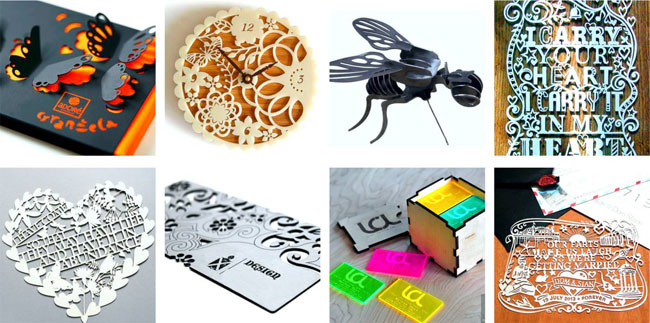

Application:

Sample: