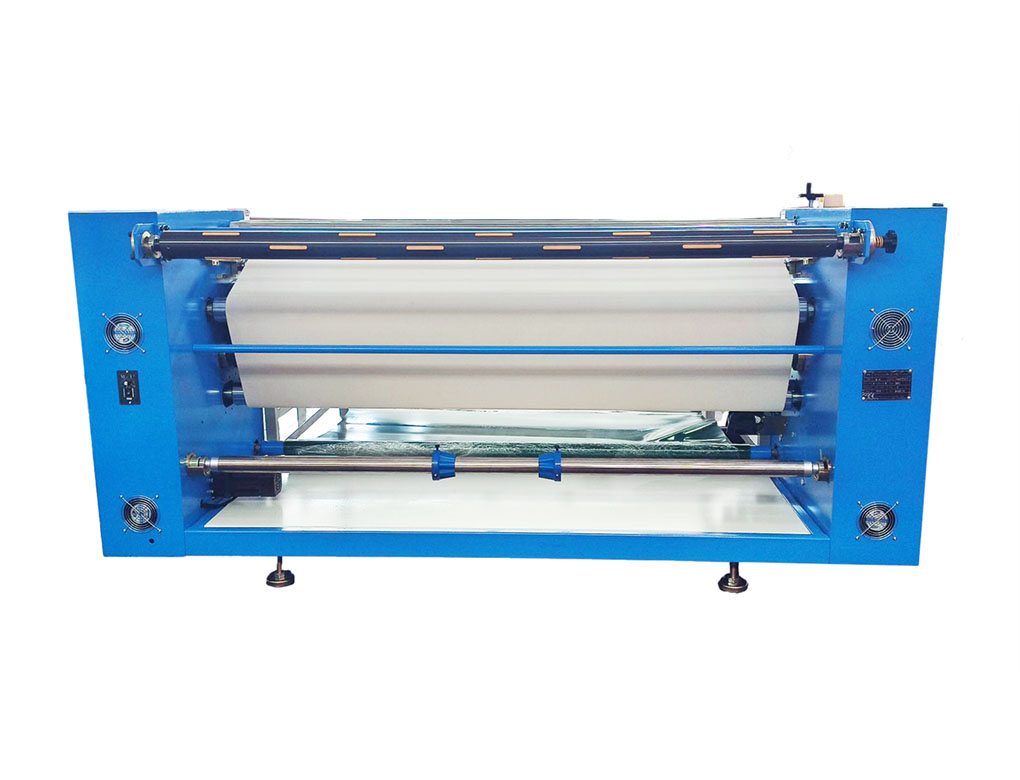

| MODELO | FT-1700-200 | |

| área máx de trabajo | 1700mm | |

| Diámetro del tambor | 200mm | |

| Velocidad de trabajo | 40-50m/horas | |

| Modo de calentamiento | por aceite | |

| Potencia de la máquina | 12Kw | |

|

|

|

|

| Temperatura máx | 0--240℃ grados Celsius | |

| Requerimiento eléctrico | Bifásico 220 V AC 50Hz | |

| Tubo de Calentamiento | 5 pz | |

| Mesa de trabajo/largo | 1500mmm | |

| Embalaje(LxWxH)-mm/peso | 260X80X135cm /550kg | |

| tamaño de vidrio(L*W*H) |

|

122*179*10cm |

This machine applies to large banners, flags, non-woven fabrics, apparel fabrics, towels, blankets, mouse pads and other products for sublimation transfer, especially continuous transfer printing for bales of cloth.

Features:

1.This machine adopts the carpet produced by “Shanghai joint venture factory” with United States imported DuPont materials, thickness of 10mm,transfer effect is good and it can be used for long time.

2.The roller adopt 100% seamless roller ,the outer roller /inner roller is dealt with precision work, and then plated Teflon, to ensure consistent temperature of each point. You can choose single cylinder or double cylinder. Double-cylinder can heat more uniformity, no chromatism, saving the power 20%-30%. Taiwan stainless steel heating pipe heat reservoir directly, reaching 200℃ within 45 minutes.

3.The side plate of machine adopts the thickness of 10mm stainless steel plates which is dealt with laser cutting .( High precision, the error is smaller)

4.Each tune off-axis is dealt with precision work and then plated platinum, error control is less than 2 u, so that the carpet does not go astray in normal conditions.

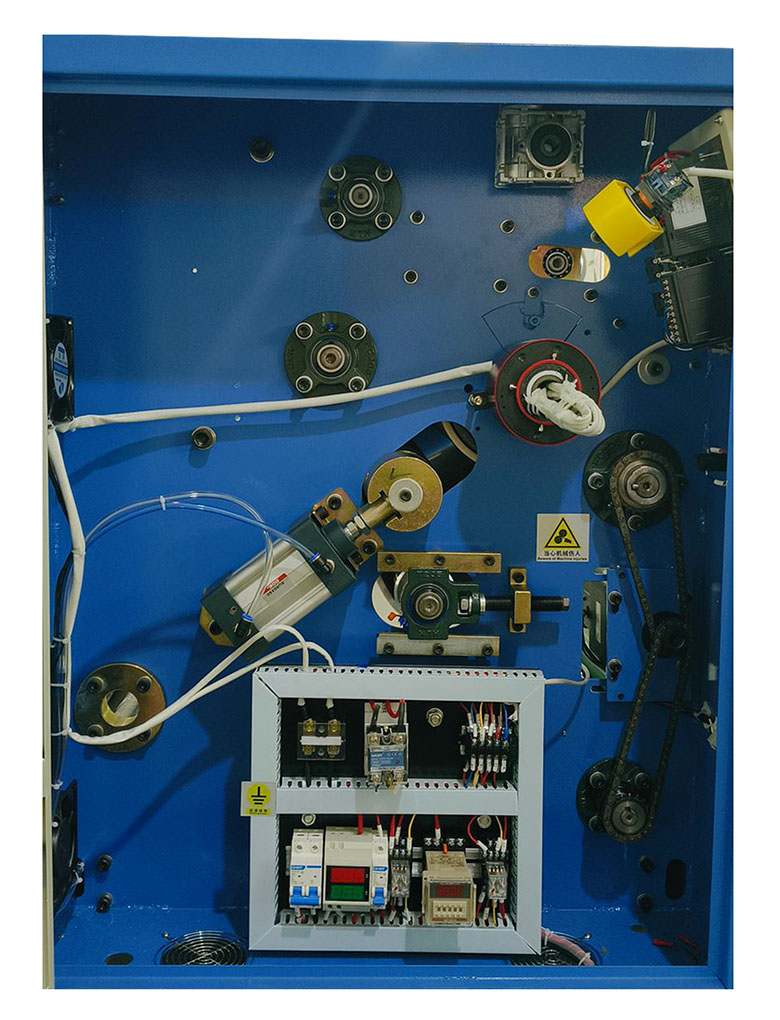

5.Electric control provides high-quality digital display with higher precision of temperature and time .

6.Imported frequency variable motor can adjust rating pressure speed according to different transfer material .

7.Carbon brush achieves conduction heating with more stable and safe electrical conductivity .

8. (Pneumatic pressure achieves better effect of transfer printing with bright colors.)

9. (If shutdown or blackout happens , the carpet can separate from roller manually for better protection of carpet and extending its service life.)

10.Transmission function of the transport tape can carry products to the behind of falsework after printing with advantages of high efficiency and power-saving. In addition , you can choose the direction of transmission.(Especially apply to pieces-cutting)

11.The machine has function of 3 placement and 2 collection which can be custom-made to suit customer’s request. You can choose to put away or placed inflatable shaft for better positioning.

12. (Multifunctional oil transfer roller printing machine is suitable for cut pieces, bales of cloth and clothing, bags, mouse pads, textile and so on. Roller diameter is optional : 420mm / 600mm / 800mm

regular width: 1.2m/1.7m/2.0m/2.2m/2.5m. (It can be produced by customer’s request)

Specifications:

Heating Type:oil

Drum Diameter:7.9in/200mm

Temperature Range: 32℉ - 750℉/0°C - 399°C ,suggested temperature under190℃ - 230℃ (374℉ - 446℉)

Power Consumption:6kw

Power Requirement:220V, 50/60Hz, 1 phase,27A

Machine Size:82.7in x 92.1in x 53.1in/2100mm x 2340mm x 1350mm

Table Top Size:47.2in x 59in/1200mm x 1500mm

Shipping Dimensions: 84.6in x 36.6in x 52.8in/2150mm x 930mm x 1340mm

Weight (GW):2156lbs /980kg

Details:

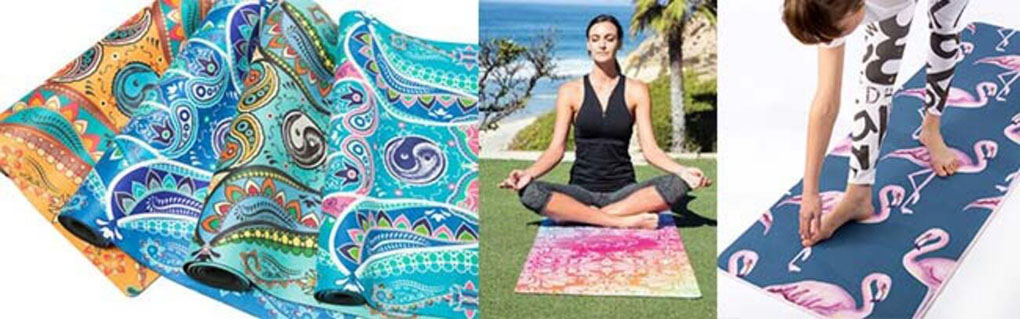

Application:

1.Flag and Banners

2.Table Cloth & Display

3.Home Textiles

5.Yoga Mat