| Nombre | width | Length | Release Paper | Glue | Precio |

| Papel para Sublimacion 1.12*100M 90g | (1.12m) | 100m | 90g | White | |

| Papel para Sublimacion 1.12*100M 100g | (1.12m) | 100m | 100g | White | |

| Papel para Sublimacion 1.62*1000M 40g | (1.62m) | 1000m | 40g | White | |

| Papel para Sublimacion 1.62*300M 50g | (1.62m) | 300m | 50g | White | |

| Papel para Sublimacion 1.62*200M 70g | (1.62m) | 200m | 70g | White | |

| Papel para Sublimacion 1.62*100M 90g | (1.62m) | 100m | 90g | White | |

| Papel para Sublimacion 1.62*100M 100g | (1.62m) | 100m | 100g | White | |

| Papel para Sublimacion 3.2*100M 100g | (3.2m) | 100m | 100g | White | |

| Papel tisu Gris para Sublimacion 1.62*500M 40g | (1.62m) | 500m | 40g | White |

Contorno de alta calidad

• Vida en almacenamiento: 2 años .

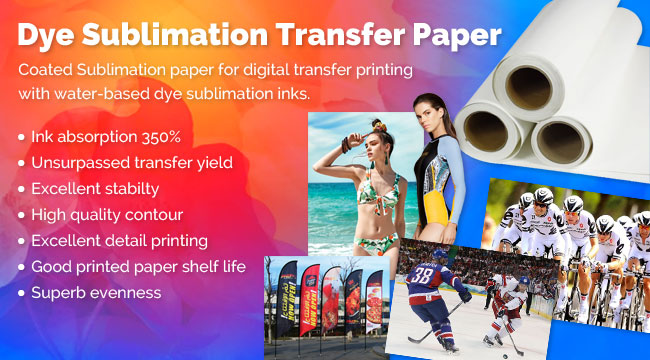

Este papel esta hecho en Corea. Es un papel de sublimacion con un 400% de absorcion de tinta y con alto rango de transferencia de calor. Este papel es compatible con todas las impresoras con cabeza tipo piezo incluyendo epson (Ricoh no compatible).

Especificaciones:

Largo: 328 (10000cm)

GSM: 40/50/70/90/100g

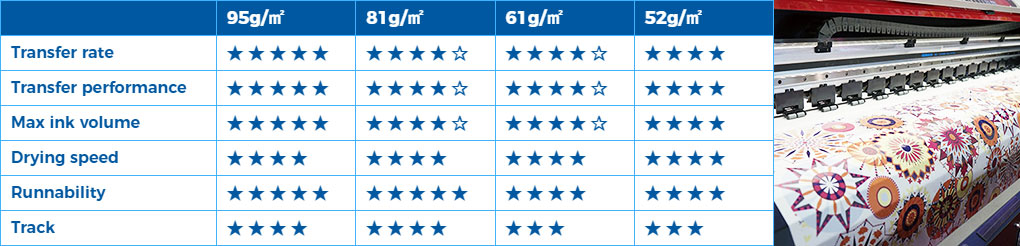

MEXICO DF-95gsm 1.62X100M Dye Sublimation Paper Roll for Heat Transfer Printing 3in Core(Local Pick-Up)

Our 95gsm Sublimation Paper can meet the use of 350% ink volume, can meet most of the high-end processing needs, and ensure excellent stability, high processing quality and processing efficiency.

Description:

• Substance 95GSM.

• Ink absorption 350%.

• Unsurspassed tansfer yield.

• Excellent stablity.

• High quality contour.

• Shelf-life: 3 years.

• Suitable ink systems: Water - based sublimation

Characteristics:

Specification:

Width: 64" (162cm)

Length: 3280' (1000m)

GSM: 95g

Recommended transfer settings: 215℃, 20s

(Ideal settings may vary based on the process, print environment & textile.)

Storage Condition:

·Storage life: three years

·Perfect packing

·Stored in an airtight environment with air humidity 40~50%

·Before usage, it is recommended to keep it for one day in the printing environment.

Recommendations:

1 . The product packaging has been well treated from moisture, but it is recommended to keep it in a dry place before used.

2. Before the product is used, it needs to be opened in the printing room so that the product can reach a balance with the environment, and the environment is best controlled between 45% and 60% humidity. This ensures a good print transfer effect and finger touching the print surface should be avoided during the whole process.

3 . During printing process, the image must be protected from external damage before the ink is dry and fixed.

Applications:

Apparel

-Lycra materials - cycling

-Polyamide - Swim & Surfwear

-100% polyester(stretch) - cycling, running, icehockey wear

Availability

-Flags

-Banners

-Felts

-Gaming tables

-Home textiles

Hard substrates

-Ceramics

-Metal plates

-Skis

-Snowboards

Operating procedures:

Customer's Case

I'm selling the fabric on Facebook. I need a lot of papers pers month. And this is my first time to order from Sign-in-china. I'm very satisfied with the papers. Hope to do more businesses in the future.

Package: